In order to construction needs, in many places need to install stainless steel railing column, stainless steel railing column and glass for the combination of installation, through the combination of glass and stainless steel two give a whole very modern and beautiful visual feeling, whether it is a pedestrian bridge, landscape area, subway station, garage entrance, shopping malls, community stairs, home installation and other places are very suitable, it brings people open, bright, spacious feeling It is very contemporary and modern aesthetic standards.

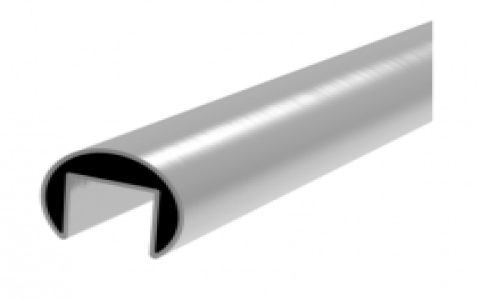

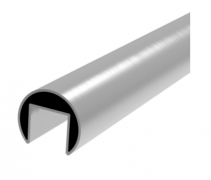

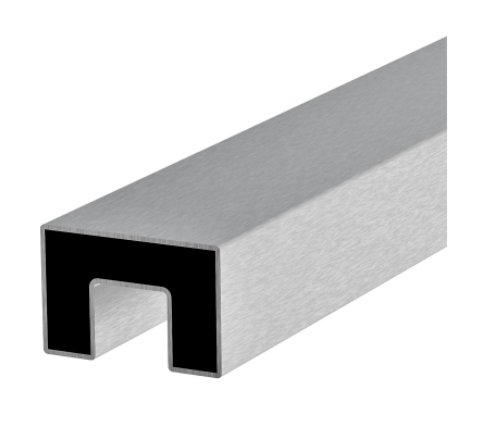

Stainless steel railing column has the main body and handrail, railing column and pre-built plate between the connection fixed by expansion bolts, after fixing, in order to make the ground style beautiful, usually pre-built plate is invisible, this way can also solve the problem of theft. Stainless steel handrail is made of pipe or oak and other materials, handrail and column between the handrail through the handrail connector, the use of screws to fix, generally screws are fixed in the bottom side of the handrail, if the stainless steel handrail, you can also use the welding method.

Stainless steel railing column construction process includes: stainless steel railing column pre-installation, stainless steel railing column steel frame production and installation, stainless steel railing column glass installation and stainless steel railing column play sealant and cleaning treatment of the four steps, the four steps are in accordance with the sequential progression, where the pre-installation is a very important link, pre-installation is not strong, is not a fit, for the future installation of glass and the overall The safety issues will have an impact, precisely because the pre-buried parts play a supporting and connecting role, so it is the key to the entire construction.

Stainless steel railing column pre-installation is divided into the following steps.

First of all, according to the drawings for pre-buried parts of the material work, the material according to the size of the drawings, and then into the material above the punching, and grinding and other deep processing, in order to ensure the quality of the future pre-buried parts, can make it use for a long time, pre-buried parts to rust removal treatment, when necessary, spraying anti-rust paint, processing pre-buried parts to get the site in place, according to the drawings on the fixed point will be fixed pre-buried parts, after verifying the size Welded solid, unsuitable place to adjust, in order to look good and to ensure the success of the later installation, to weld the surface of the garbage caused by the weld and the weld is not smooth place to polish smooth, anti-rust paint off the place to make up the brush, otherwise, here will be the first eroded place, make up the brush must be done meticulously.

Stainless steel railing column use a wide range, the future will have the trend of expansion, in its installation must be stable and steady, do a good job every step to ensure the quality of the whole project, to reduce the consequences.